Have you ever seen the movie, The Martian? Stranded on Mars, the movie’s leading character uses the limited resources available to grow potatoes to survive. At Chiba University, Prof. Eiji Goto is working to make this “space farming” a reality. We talk to him about how he expanded the scope of his research projects from Earth to outer space through interdisciplinary collaboration.

Environmental control engineering

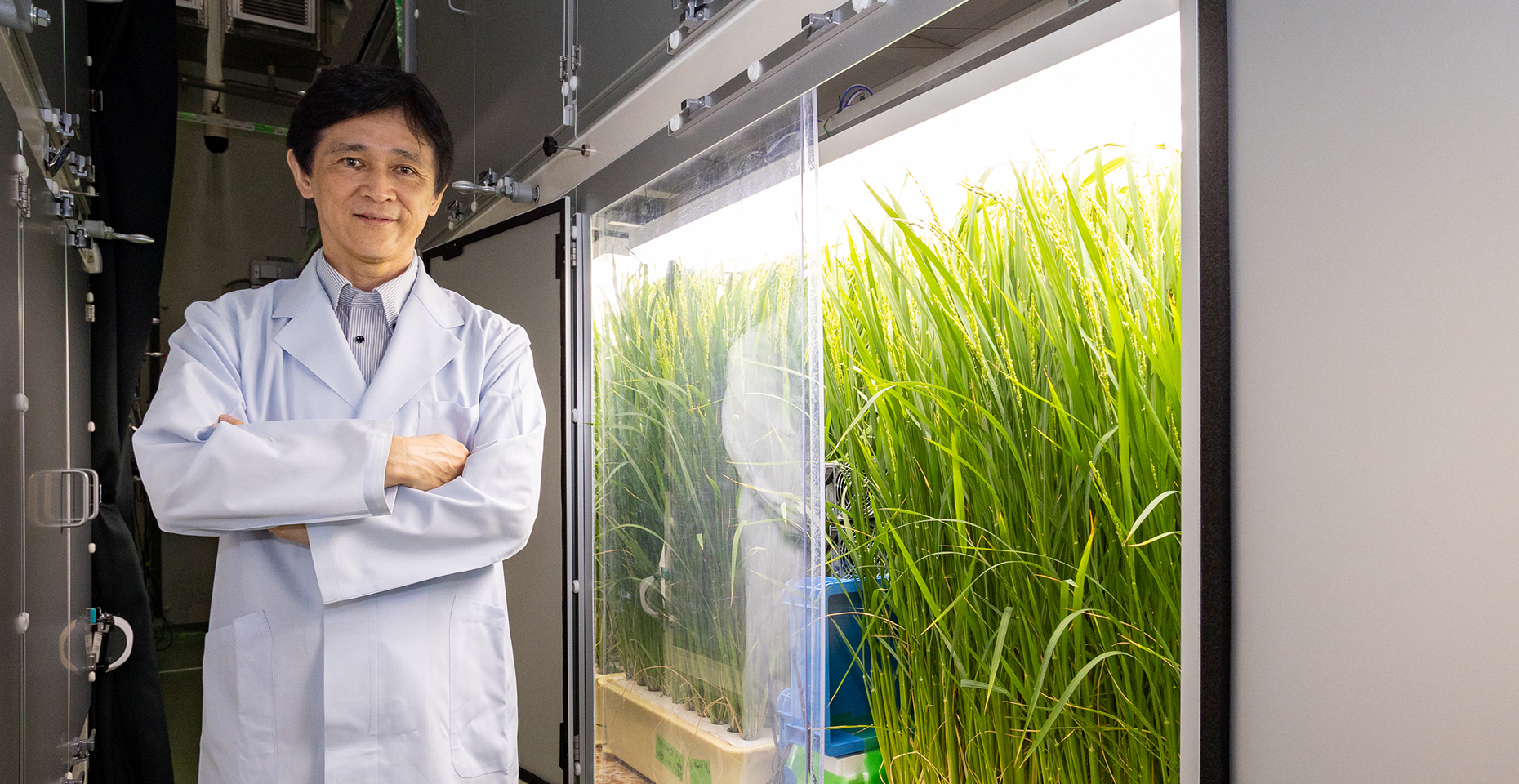

The main focus of my research is environmental control engineering, the field of research in which we strive to create an optimum environment for plant growth. In the natural world, even if we plant seeds at the same time, there are differences in plant growth rate and crop/fruit size/yield. These differences stem from variations in the water and nutrients present in the environment around the plants’ roots, the duration of the plants’ exposure to sunlight, and the location where we plant them.

In general, the quality of seeds sold in Japan is quite good, and as such, differences in plant growth are largely due to the external environment. To produce vegetables of consistent quality, we explore the optimum environmental conditions that can ensure uniform plant growth rates. Such a perfectly controlled environment for plants is called a “plant factory.”

A plant factory does not renounce traditional farming practices. A plant factory aims to address the challenges faced by traditional farming, such as the increasing demand for nutrient-dense vegetables with consistent quality, the decrease of farming populations, and the food supply crisis.

Why a plant factory?

A plant factory has seven major advantages. First, because the growth rate of the plants is controlled and not affected by the weather, we can expect a consistent harvest from each seeding. Second, one can participate in farming without having farming skills or experience, because a plant factory is managed by IT devices and artificial intelligence (AI).

The third merit is that the harvesting is done by robots, which bypasses the physical labor of harvesting. Fourth, we can construct vertical multilayer cultivation fields in a factory so that we can optimize how we use our limited space. Fifth is that we don’t need to use pesticides because there are no pathogens or pests in the factory.

Sixth, we can re-circulate and recycle the water used in the factory because it is a closed environment. And finally, we use energy-efficient LED lights in the factory, thereby eliminating the need for natural sunlight. Another advantage of LEDs is that we can change their color. It is known that vegetables grown under red light tend to be soft and palatable, while vegetables grown under blue light tend to contain larger amounts of functional components, such as polyphenols. This means that we can adapt the vegetables we grow to best suit our needs.

Medicinal plants

Until I joined Chiba University, my research subjects were vegetables for food supply and ornamental flowers. However, since I began working at this university, I have come across several medicinal plants that I had never seen before. Some medicinal plants grow only in certain regions, and their scarcity can delay research or raise the prices of medications based on those plants. I thought that, using my experience in a plant factory, this is a problem that I could solve.

Now, I work in medicinal plant research, exploring the environmental conditions in which these plants can grow steadily. Because plants are immobile and cannot move on their own to better locations with better environmental conditions, the onus is on us to provide the ideal environment for them. We study the environmental conditions that enhance plant growth, such as temperature, rainfall, sunlight exposure duration, and soil quality. Fortunately, nowadays, it is possible to obtain such data from online databases.

However, the optimal conditions for plant growth vary depending on the growth stage; therefore, we must consider numerous factors throughout the plant’s lifetime. There are occasions where I have to apply the intuition I have gained from my past experience, in addition to scientific data, to set up the best conditions for plant growth. This intuitive aspect of running a plant factory is similar to how farmers use their experience-based knowledge in traditional farming. Sometimes, students and other researchers tell me, “I wish we could put your intuitions in a database.” However, intuitions are hard to define in a concrete manner, and therefore, it will take some time to develop such a database.

Expanding possibilities with interdisciplinary research

In my late thirties, I started feeling that my research was really on the right track. At the same time, I began to feel that it would be more exciting to engage in research with other researchers and not keep my research so isolated. Therefore, I started to interact with researchers in other fields.

One medicinal plant that is growing in demand is chabo-inamori (Ophiorrhiza pumila), an essential ingredient used in anticancer drugs. Together with Prof. Kazuki Saito, formerly of the Graduate School and Faculty of Pharmaceutical Sciences at Chiba University, and Prof. Masami Yamazaki’s research group, we determined the ideal growing conditions for chabo-inamori. Prof. Saito is now the Director of the RIKEN Center for Sustainable Resource Science (CSRS).

Oral vaccines

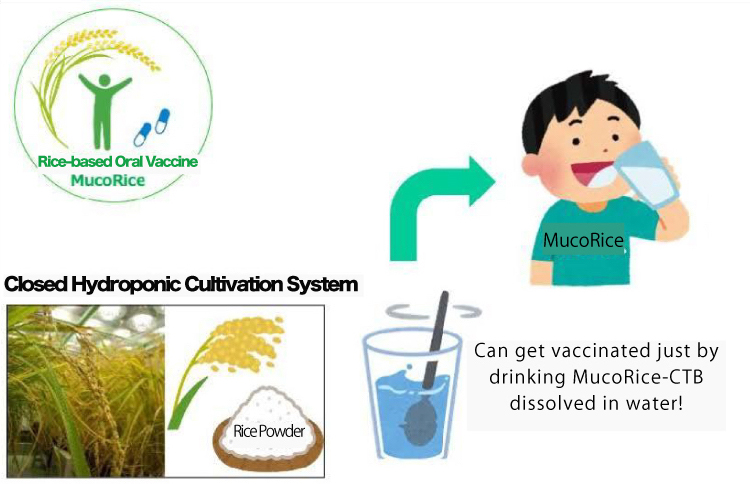

Another collaborative project I worked on was the development of an oral vaccine. For this project, I worked with Professor Hiroshi Kiyono of the Future Medicine Education and Research Organization at Chiba University. We developed a completely closed hydroponic cultivation system for growing rice to be used for a rice-based oral vaccine, MucoRice-CTB, which is used against mucosal infectious diseases such as cholera.

Vaccines are usually injected into the arm as a liquid. MucoRice is in the form of powdered rice, and patients dissolve the powder in water and drink it. MucoRice circumvents the pain associated with injections, which makes it easier for healthcare workers to administer, especially for pediatric patients. Because it is a powder, transportation and storage costs are relatively low, and handling the vaccine is much easier than handling conventional glass ampoules.

Using this hydroponic system, plants used to produce vaccines can be grown anywhere in the world. This will help reduce vaccine inequities among countries, such as what happened during the COVID-19 pandemic. I am happy to state that my research can contribute to the wellness of people around the world.

Space farming

A new project I am working on is space farming, i.e., growing plants in space. I am investigating the possibility of establishing plant factories on the moon and the International Space Station (ISS). NASA, JAXA, and SpaceX are advancing space transportation technologies, and in the future, we might be able to stay in space for much longer periods of time. This means that we now need to think about a stable food supply in space.

There is already a variety of space food that has a long shelf-life. However, if we are staying in space for an extended period of time, we will miss consuming fresh food. We also need to anticipate and prepare for an emergency where we might run out of stocked food in space. As such, in collaboration with JAXA, we started a research project in 2017 to grow crops in space. Furthermore, in concert with corporations and other universities, we conducted the world’s first experiment for growing lettuce in Kibo, a Japanese science module for the ISS developed by JAXA.

The lettuce was grown in a small, sealed bag containing sterilized lettuce seeds wrapped in a non-woven fabric. When space residents need lettuce, they can soak the bag in a specially formulated culture solution—which will cause the seeds to germinate—and then grow them under the appropriate light. The biggest advantages here are that the cultivation method does not require large-scale equipment and that the system is easy to maintain. Because the lettuce is cultivated in a closed environment, resources, such as water and CO2, can be circulated and reused, and no odor is generated. The cultivation environment is virus-free, and therefore, pesticides are not necessary either. Even in case of contamination, with mold, for example, the damage is minimized because the seeds are individually packed.

Challenges in outer space

Gravity has a significant impact on plant growth. One problem with space farming is that there is only very weak gravity, i.e., microgravity, on the ISS. Air convection does not occur in the absence of gravity and this causes the plant’s temperature to increase, which ultimately stunts its growth. Also, without gravity, water evaporation from plants is reduced, and the ability of plant roots to absorb water is weakened. The current challenge for us is to find a way to maintain adequate airflow for the plants.

Some people might think that plants grown in space will not taste the same or that they might lack necessary nutrients. We are still evaluating this, but so far, we’ve found that the taste and nutrition levels of crops grown in space are the same as those of crops grown on Earth. Moreover, cultivation in zero gravity does not seem to increase the levels of elements that normally do not appear in vegetables grown on Earth. We plan to improve our space farming equipment and experiment with more varieties of vegetables.

Developing cyclic ecosystems on the moon

.jpg)

In addition to food production, we are conducting research to develop bigger cyclic ecosystem cycles in space, including waste recycling and with zero emissions. I am also the sub-leader on another space project that is investigating the possibility of constructing a colony on the moon. The gravity on the moon is 1/6th that on Earth, and the lunar surface is bombarded with radiation. Growing plants under these conditions will require unprecedented research and development. The Academic Research and Innovation Management Organization, Chiba University, has announced that it will support our lunar project. We aim to take full advantage of this glorious opportunity, collaborate with researchers from different fields, and advance the prospects of lunar farming.

Series

From Drug Discovery to Space −At the Forefront of Bio Research−

The promotion of biotechnology is indispensable to achieving SDGs and improving the QOL of our people. We look into the unique research that our top leaders in Biotechnology and Life Sciences are challenging.

-

#1

2022.07.26

Non-Injectable Mucosal Vaccines Providing Safe and Less Stressful Immunization

-

#2

2022.07.26

Understanding the Relationship between Diseases and Membrane Protein Structure

-

#3

2022.09.02

Developing next-generation drones: learning from insects and birds

-

#4

2022.10.06

Plant factory: sustainable plant production on Earth and in outer space

-

#5

2023.01.14

Mimicking the 500 million years of plant survival strategies to create a sustainable future

-

#6

2023.03.17

Interdisciplinary Collaborations to Solve Social Issues: Frontier Bioresearch at Chiba University

Recommend

-

Decoding Epigenome Modification Errors: Exploring Immunological Mechanisms by a Two-way Player in Biology and Data Science

2024.06.27

-

Examining Social Injustice of Modern Society through “Child Poverty”: Creating a Society Where Every Parent is Respected, and Every Child Thrives

2023.05.26

-

Non-Injectable Mucosal Vaccines Providing Safe and Less Stressful Immunization

2022.07.26